Comprehensive Injection Mold Design Services

Explore Our Turnkey Injection Molding Solutions

Design to delivery and everything in between is what we do best. We bring the upfront injection mold design and innovation to the forefront and implement custom manufacturing and assembly solutions for your product. We offer various injection molding technologies including traditional injection molding, micro, insert over molding, 2-shot, cube, stack, needle-over molding, vertical molding, gas assist, in-mold labeling, and liquid silicone rubber (LSR). With over 400 injection molding machines including various cavitation capabilities, we are able to provide custom manufacturing solutions for any product in the Medical, Pharmaceutical & Diagnostics, or Consumer markets.

Discover how we leverage decades of injection molding experience to engineer innovative designs beyond your imagination.

Micro Molding Capabilities

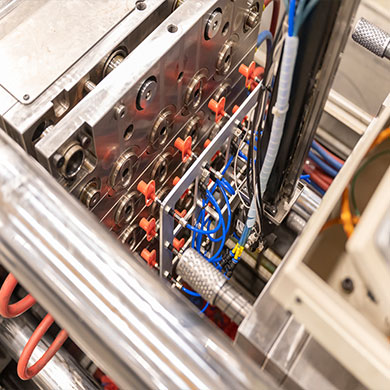

Leveraging the latest technology in the industry is a core competency here at Tessy. When it comes to tight tolerance micro molding, we’re the experts. We have over 40 micro molding machines throughout our facilities for a wide variety of applications. Our micro molding capabilities include:

- Ability to mold tolerances down to .0005 total and +/- .001 routinely

- Shot weights as small as .07 oz.

- Horizontal and vertical molding

- Micro press integration into automated assembly equipment

- Insert over molding

Design for LSR Molding

Tessy is also an industry leader in high volume Liquid Silicone Rubber (LSR) injection molding. We are quickly approaching 10 LSR injection molding machines running production with an annual quantity of parts over 200M units. To support LSR production programs, we provide the following injection mold design and integration expertise:

- Mold cavitation up to 64

- High precision dosing systems

- R&D development support for LSR replacement testing of legacy materials – including polyisoprene

- Integration into automated assembly lines with proprietary part feeding systems

Want to learn more about LSR in the medical industry? Read our article, The Role of LSR Molding in Medical Device Manufacturing.

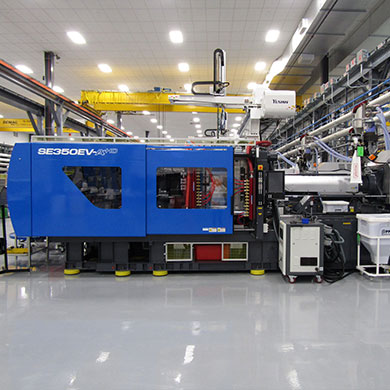

Access State of The Art Machinery

Our machines range from 3 tons up to 720 tons with available capacity in all press size ranges. We partner with best-in-class molding machine manufacturers across the world to ensure solutions that are robust as they are agile. Our strategic partnerships allow us the ability to provide the best press for the application based on your needs and help ensure that we are always leveraging the latest technology in our custom injection mold designs. Whether you’re developing a tight tolerance micro-molded medical product or a high-volume consumer good for production, we’ve got you covered.

We differentiate ourselves with creative solutions by combining any number of the above technologies to provide our customers with the best quality, delivery, and total value for any program.