Custom Engineering Solutions

COMPREHENSIVE SOLUTIONS THAT REINVENT

INDUSTRY STANDARDS

With 230+ highly-skilled engineers on staff, Tessy is small enough to

move swiftly and work closely with your team—but our impact is huge.

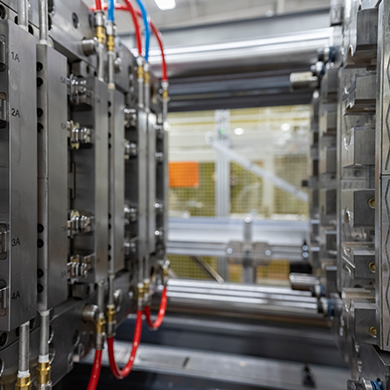

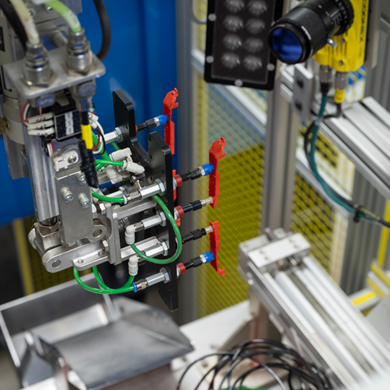

Our team delivers quality products, tooling, and automation using a

4-step process that includes:

- DFM analysis and automated assembly evaluation

- Building Custom molding and assembly equipment

- Manufacturing product to your standards

- Data monitoring and continuous improvement

A CUSTOMIZABLE PROCESS FOR STRONGER SOLUTIONS

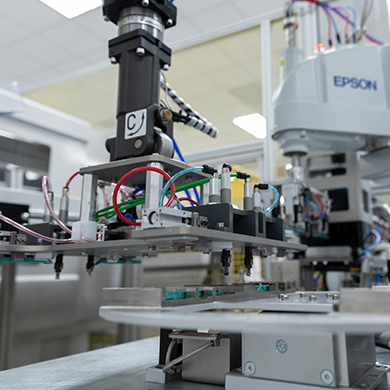

Our advanced product design capabilities, rapid prototyping, and dedication to continuous improvement are just a few of the things that set us apart. Our process to create custom engineering solutions involves leading-edge research and development to ensure that your product is refined and crafted using the most advanced techniques. We accomplish this through a comprehensive approach to plastic injection molding that includes solution exploration, feasibility studies, and pilot runs– adding value to your project no matter where you are in the design process.

YOUR MANUFACTURING SOLUTIONS,

DELIVERED WITH SPEED AND IMPACT

At Tessy we pride ourselves on being fast, nimble, and thorough in developing solutions that meet your unique needs. We take a “fail fast” approach, where our R&D Team develops, tests, and refines numerous prototype designs efficiently with a fast turnaround. This process saves valuable time and pushes the path forward on identifying features of acceptable, unacceptable, and exceptional designs.

Our process allows us to eliminate multiple designs before moving forward with the design that will exceed customer expectations, and ultimately accomplish all of the following while reducing your overall investment:

- Multiple design iterations

- 3D printed component samples within 1-2 days

- Digital ABS 3D printed mold cavities within 2-4 days

- Aluminum mold samples within 1-2 weeks

- Rapid assembly, design, and testing

Our comprehensive plastic injection molding expertise combined with new technologies, like metal injection molding and the latest in additive manufacturing, make Tessy an invaluable partner in your product development and manufacturing processes.